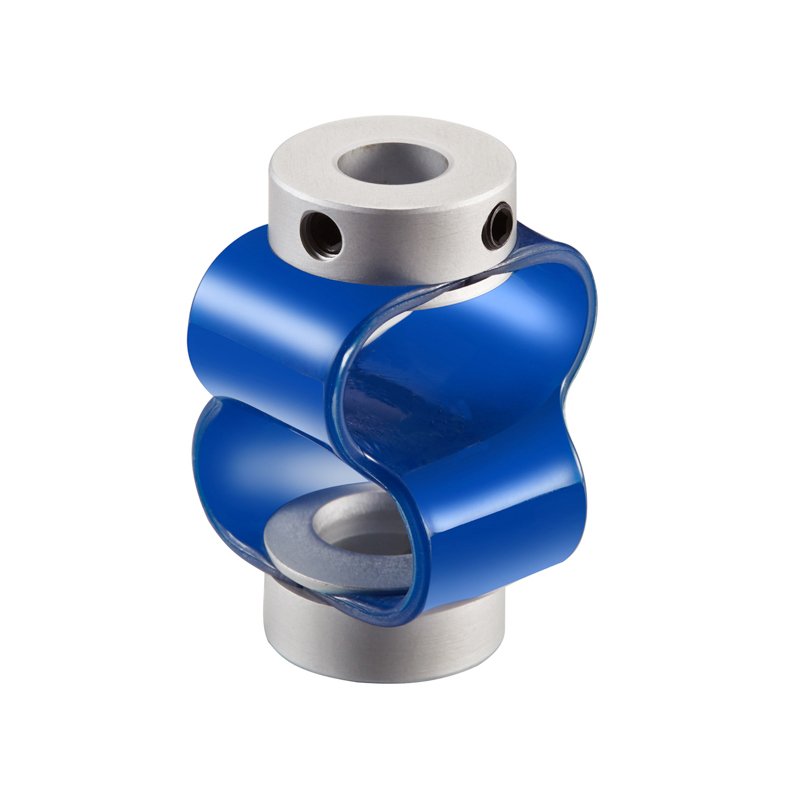

Lb Series shaft Metal Clamping Plate Flexible Coupling

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded.

online service

In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects.

Use and characteristics

High torque rigidity and high sensitivity.

Zero rotation gap.

Clockwise and counterclockwise rotation characteristics are exactly the same.

Stainless steel diaphragm compensates for angular and axial deviations.

Applications

1. Widely used in various mechanical and hydraulic fields

2. Small dimension, low weight, high transmitted torque

3. Elastomers made of polyurethane with shore hardness between 80-98

4. Compensating the axial relative drift, buffer and vibration reduction

5. Material: cast iron, steel and aluminum alloy

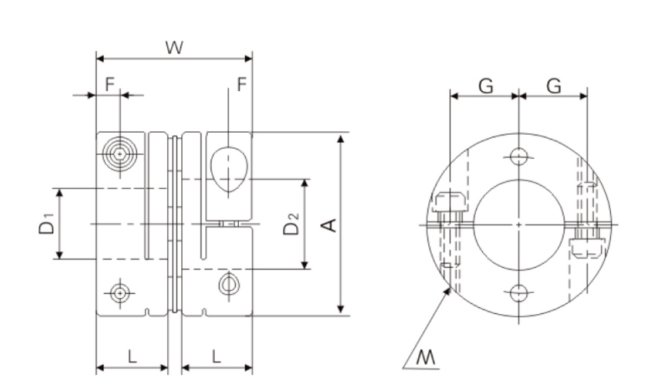

Dimensions

Product features

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

LB Series Metal Bellows Clamping Flexible Coupling

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded.

Learn MoreLP 6x6 D16 L24 series coupling encoder motor torque spring Flexible coupling

◆introduction

Flexible couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

LS Encoder 8-shaped coupling stepping servo motor torque Flexible couplings

◆Feature:

Steel hubs are zinc plated.They are precision swaged by a lifetime crimp to unique double loop element made form ELASTACAST polyurethane.The hubs fix to sharts by metric set screws.Maximum operating temperature is 80℃.

YUMO 6mm Plastic Quick Encoder Coupling

Plastic type;

It can be applied to connect the eccentric shaft, can greatly adjust concentricity;

It can adjust the height of the products in the scope of use.

Model:LS D20-30 -L40 6*8.2

Brand:YUMO

Code:YM0000541

MOQ:25