LP series coupling encoder motor torque spring Flexible coupling

◆introduction

Flexible couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

online service

1. Widely used in various mechanical and hydraulic fields

2. Small dimension, low weight, high transmitted torque

3. Elastomers made of polyurethane with shore hardness between 80-98

4. Compensating the axial relative drift, buffer and vibration reduction

5. Material: cast iron, steel and aluminum alloy

Use and characteristics

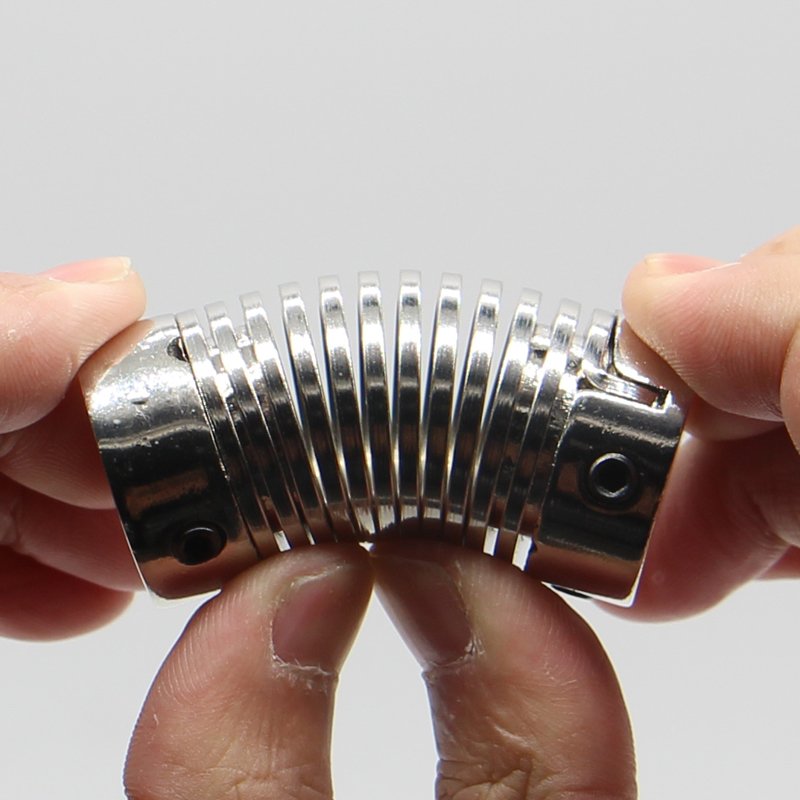

High torque, high torsional rigidity, high response.

Zero gap.

The presence of bias can also maintain constant velocity motion.

Softness, stainless steel spring can tolerate eccentricity, deflection angle and axis deviation wide error, adjustable.

Standardization of products with different diameters at both ends.

Applications

1. Widely used in various mechanical and hydraulic fields

2. Small dimension, low weight, high transmitted torque

3. Elastomers made of polyurethane with shore hardness between 80-98

4. Compensating the axial relative drift, buffer and vibration reduction

5. Material: cast iron, steel and aluminum alloy

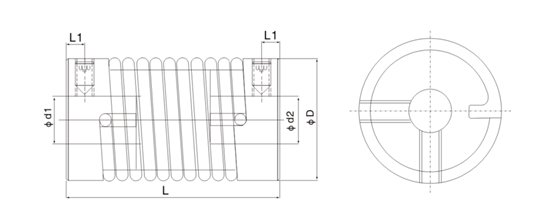

Dimensions

Product features

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

BF1 Series 10-28mm Aluminum Alloy Full Encoder Coupling - OD55mm* L78mm

With one hole diameter measuring 10mm and the opposite hole diameter measuring 28mm, this full encoder coupling is the reliable and economic solution for the connection of shafts, allowing for the transmission of power. This critical connector piece features a durable aluminum construction offering resistance to wear and tear and reliable, long-term performance. This particular coupling features an outer diameter of 55mm and a length of 78mm.

Learn MoreSingle Disc LD2 encoder coupling

introduction

Flexible couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

Cross Slider Top wire Oldham coupling screw stepper servo motor torque Flexible couplings

Oldham coupling consists of two half-open on the end face of the coupling groove and a disc with protruding teeth on both sides of the intermediate composition. Protruding teeth can be due to the slide in the groove, it can compensate for installation and operation when the relative displacement between the two shafts.

Learn MoreLD Single shrapnel Single diaphragm coupling high torque stepper servo motor coupling Plum

Diaphragm consists of several groups with bolts staggered with two coupling halves, each of the diaphragm by a set number of sheets stacked together, diaphragm coupling by elastic deformation of the diaphragm to compensate for the relative displacement of the two axes of the Union, is a high-performance metal stronger coupling element, do not run oil, more compact structure, high strength, long life, no rotation gap, independent of temperature and oil slicks, with acid, alkali corrosion, suitable for high-temperature, high-speed, medium corrosive environmental conditions of the drive shaft

Learn More