YUMO LR2 series electric motor shaft flexible plastic quick rubber coupling

Flexible couplings are usually cut from a metal wire rod made of commonly used materials are aluminum, stainless steel, engineering plastics. Flexible coupling using a parallel or helical grooving system to adapt to a variety of bias and precision torque transmission. Flexible couplings usually have good performance and price advantage, and in many stepper, servo system, the practical application, elastic coupling is the preferred product. One-piece design allows flexible couplings to achieve a zero gap torque transmission and without maintenance

online service

◆Specifications

1.Industry plastics is more flexible and bearing

2.Little torque coupling with high dependability

The stepped radial slot design of the YUMO coupling provides a product that combines the high torsional stiffness of a straight beam coupling with the lateral flexibility of its helical counterpart.

YUMO coupling is moulded from a plastic capable of withstanding temperatures up to 150°C. This provides economic advantage to the customer and gives the coupling a low inertia which, combined with its other performance characteristics, makes it ideal for driving encoders and for applications that require electrical isolation and corrosion resistance

◆Features

* Single or double plate springs, optional to customer.

* Zero backlash.

* Excellent response and high torque capacity.

* Identical clockwise and anti-clockwise rotational characteristics.

* One-piece metallic spring coupling, 2 screws for clamping.

* For servomotor, step motor connection.

* Material: Engineering plastics

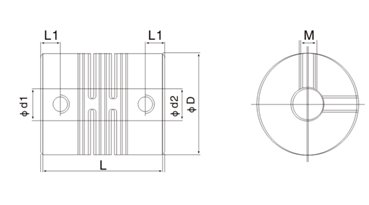

* M: The hole dia. Of the encoder end. N: The hole dia. Of the user end.

* D and L can be defined by user; Standard: Outside D=40mm, length=50mm.

* Diameter of hollow shaft can be defined by user; Standard hole 6mm, 8mm.

* Torque<25.0Nm, the axial degree <0.5mm, the corner setover<1 degree.

* Extensive application.

Dimensions

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

LP 6x6 D16 L24 series coupling encoder motor torque spring Flexible coupling

◆introduction

Flexible couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

Lb Series shaft Metal Clamping Plate Flexible Coupling

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded.

Learn MoreBF1 Series 10-28mm Aluminum Alloy Full Encoder Coupling - OD55mm* L78mm

With one hole diameter measuring 10mm and the opposite hole diameter measuring 28mm, this full encoder coupling is the reliable and economic solution for the connection of shafts, allowing for the transmission of power. This critical connector piece features a durable aluminum construction offering resistance to wear and tear and reliable, long-term performance. This particular coupling features an outer diameter of 55mm and a length of 78mm.

Learn MoreLE Series Gear Electric Motor Shaft Hight Rigid Metal Disk Coupling

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded.

Learn More